It is made of MS and outer side is coated with red oxide for long life. Plastic Spacers can also be provided so that one mold can be used to make different sizes of blocks.

We also design the molds as per the client’s requirements It is easy to dismantle and remove the blocks due to the unique design of the mold.

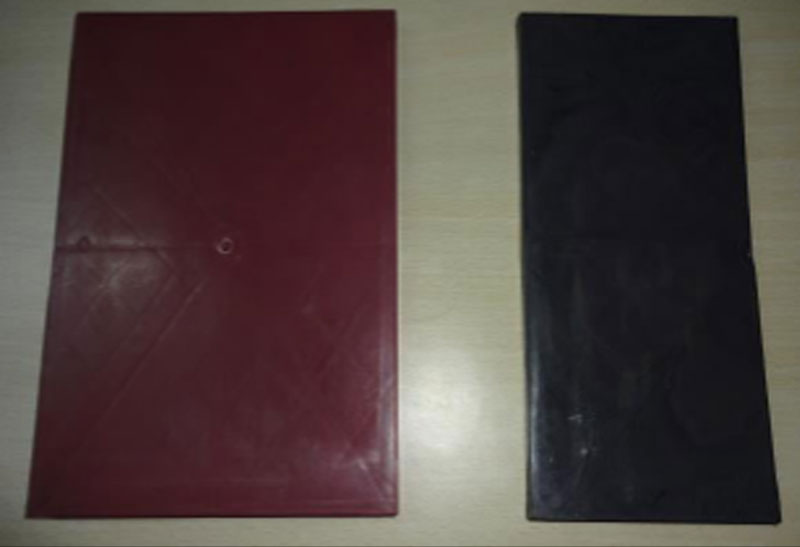

It is made of good quality plastic. With the use of this we can make different sizes of blocks in a single mold This is available in different sizes of, 4 inches, 6 inches & 8 inches etc. We can also provide the plates as per the client’s requirements. It is easy to clean and maintain.

It is made of MS and coated with red oxide for long life.

Plastic Spacers are provided so that one mold can be used to make different sizes of blocks. We also design the molds as per the client’s requirements It is easy to dismantle and remove the blocks due to the design of the mold.

It is made of MS and coated with red oxide for long life. It is made of MS and coated with red oxide and paint for long life. The unique design & mechanism ensures no jerk with removing the mold, hence no chance of breakage of ends of the blocks. It is easy to clean and maintain.

It is made of MS and coated with red oxide and paint for long life.

High tensioned wires are used for cutting which are virtually unbreakable.

The cutting sizes can be changed to suit the size of blocks required, just by twisting abolt.

The cutting is smooth due to the special type of wires used so the edges of the blocks never break, depending on temperature and environmental conditions.

It is made of MS and coated with red oxide and paint for long life.

High quality wheels are used to ensuring easy maneuvering.

The slope at the base of the trolley and its wide opening ensure easy and complete emptying of the slurry into the molds.

It is easy to maintain.

ISteam Chamber is used to maintain steam at constant pressure This helps to cure the blocks in 6 to 8 hours compared to the 21 to 28 days for water curing.

Boiler is made from High quality materials available in the market It is easy to maintain.